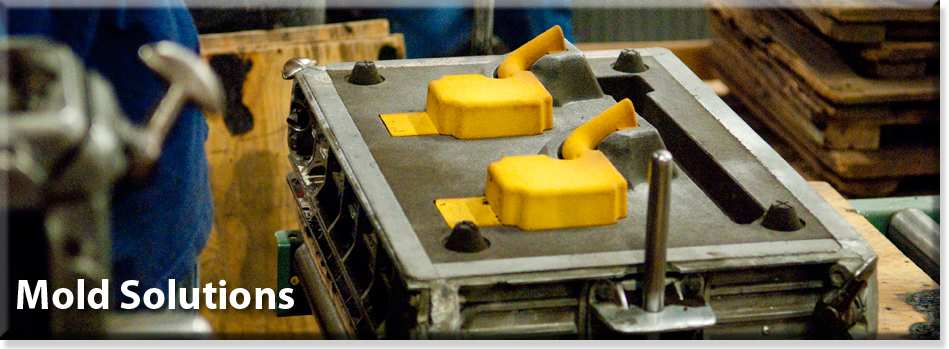

GREEN SAND MOLD

The Sand Casting process - aka Green Sand Mold process - is commonly used in the casting of aluminum, brass/bronze, and iron products.

The term "green sand" is known principally because of the moisture content within the sand. The sand undergoes a "mulling" process in which various clay and chemical additives that act as binders are blended with the sand, which results in a compound which is suitable for the sand molding process.

This prepared sand mixture is then compressed around the pattern at specific pressures and temperatures, to ensure it will maintain its shape throughout the remainder of the casting process. The blended sand and binders are compacted around the pattern, taking on the shape of the desired casting.

Sometimes the design of the casting entails internal passageways being formed into the mold. This is done by using sand cores which are made of a similar sand mixture. The cores are strategically placed to form the necessary passageways in the casting. The two halves of the mold are subsequently closed and metal is poured into the cavity and left to solidify.

After solidification has taken place, the sand is vibrated until it is released from the casting. The finishing process can then be completed by grinding, machining, plating and painting.