SEMI-PERMANENT SAND MOLD

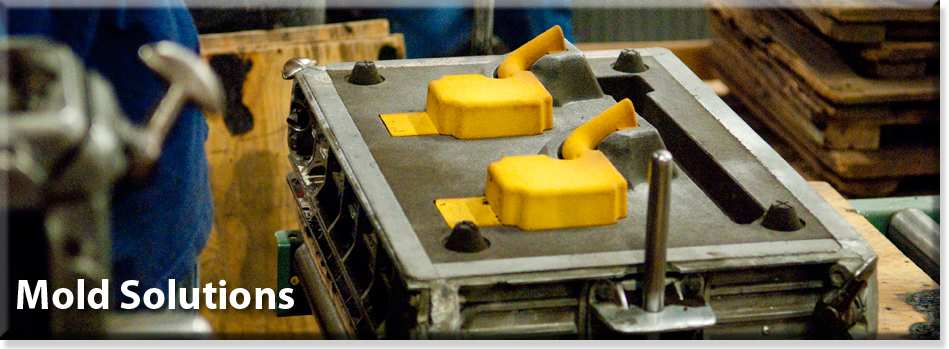

Semi-permanent mold is a casting process - producing Aluminum alloy castings - using re-usable metal molds and sand cores to form internal passages within the casting. Molds are typically arranged in two halves - the sand cores being put into place before the two halves are placed together. The molten metal flows into the mold cavity and surrounds the sand core while filling the mold cavity. When the casting is removed from the mold the sand core is removed from the casting leaving an internal passage in the casting.

The re-usable metal molds are used time and again, but the sand cores have to be replaced each time the product is cast, hence the term semi-permanent molding.

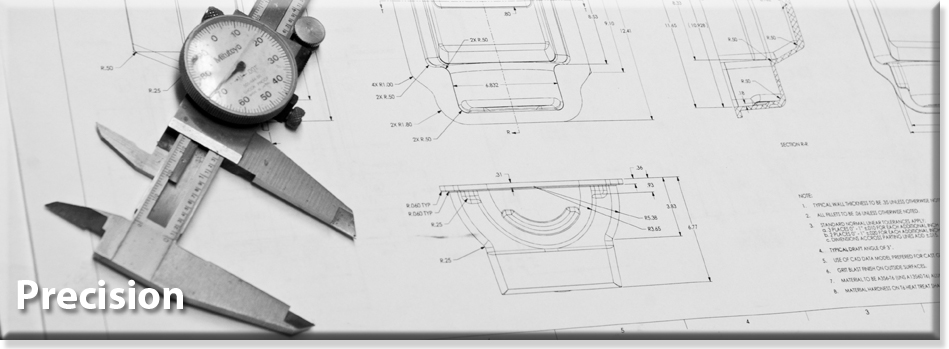

Semi-permanent molding affords a very high precision quality to the casting at a reduced price compared to the sand casting processes.